A chute magnet is a simple way of removing iron particles as small as 60 µm from animal feed, powders and more.

In the animal feed industry hammermills, palletizers, mixing, grinding or other equipment can occasionally suffer damage. Or processes entail a risk of dust explosions. Companies can also receive damage claims. Magnet systems prevent damage to expensive equipment caused by bulk flows contaminated with iron particles. The magnet systems from Goudsmit Magnetics, based in the Netherlands, can be built into vertical pneumatic conveying lines, above conveyor belts or in existing systems such as vibratory conveyors. They remove iron contamination as small as around 50 µm from bulk flows, such as maize, grain, malt, barley, sugar, cocoa beans, sunflower seeds, rapeseed, tapioca or soya beans.

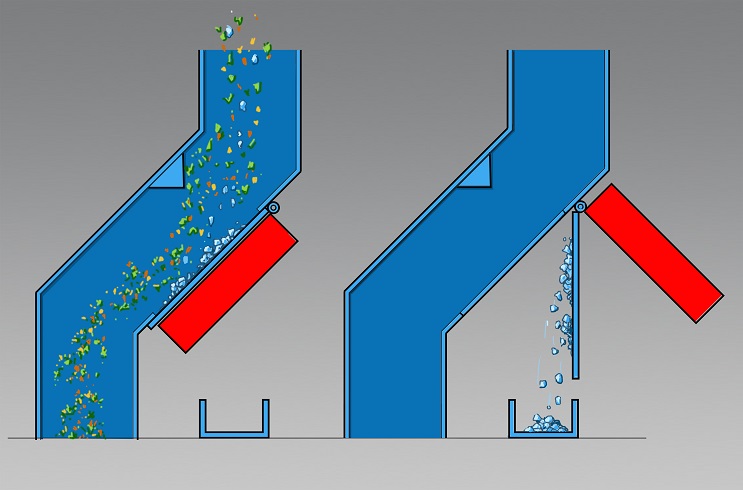

CHUTE MAGNETS

Chute magnets can be easily installed in existing free-fall or chute processes in applications such as those found in the animal feed industry. The chute magnet consists of a powerful Neoflux® (Nd-Fe-B) plate magnet that is strong yet lightweight. This magnet is a simple way of removing iron particles of approximately 60 µm to 5 mm in size from animal feed, powders and more. Important aspects for attaining good separation are that the magnet make optimum contact with the product, is easily cleanable and can also be easily integrated into existing production processes. The chute magnet has a fixed overall height but can be made to any width.

Installation

A chute magnet consists of a powerful Neoflux® (Nd-Fe-B) magnet, a hinge on which the magnet hangs, a cleaning plate and a mounting plate. During installation a location is sought where the product will make good contact with the magnet. We then make a hole in the existing ductwork at this spot and weld the mounting plate to the ductwork. The magnet is then mounted to it so the system is 100% sealed. This provides a means of safe, quick cleaning as well as optimum separation, which requires a chute angle of no greater than 45°.

Workingprinciple: https://youtu.be/cwaSB7Tme50

EASY CLEAN MAGNETIC SEPARATOR FOR POWDERS

Recently Goudsmit Magnetics has introduced a new generation of magnetic separators. This Easy Clean Cleanflow magnet is used to remove metal particles (>30 µm) from powders in the cattle feed, food, chemical, ceramic and other industries. This magnet has a user friendly cleaning, improved flow and the high Gauss values of the bars. In contrast to previous designs, in which such magnets were fitted with two layers of thin (Ø25 mm) bars, the new design contains a single row of Ø50 mm thick bars. New measurement techniques, including simulations of magnetic fields and tests in the company’s own test centre, have shown that this results in a higher separation yield. This is because the thicker bars remain in contact with the magnetic particles longer. An additional benefit is the reduced height of the magnet as a whole, which means it requires less installation height. Moreover, a single row of bars results in improved product flow; which is particularly beneficial when it comes to poorly flowing powders.

CLEANING

The pneumatic magnetic bars simplify the cleaning process. The magnetic bars are slid out along a guide and, once outside the housing, the magnets are exposed by blowing them out of the bars. A plate then retains the captured metal particles, after which they fall into a collection tray.

With its enormous magnetic holding power of 12,000 Gauss at the rods, the Easy Clean flow magnet is also perfectly suited for the separation of small stainless steel particles. The tests and measurements mentioned above also showed that magnetic holding power alone is not enough to separate stainless steel particles. It is also of critical importance that these particles come into contact with the bars as they flow past. To accomplish this, the company can fit deflectors in the magnet, providing good control over the direction of product flows containing weak magnetic (stainless steel) particles. This ensures that the product always contacts the bars

Workingprinciple: https://youtu.be/p6uXKYvQF3Y

————————————————————————————————————————-

For more information please contact:

Peggy Ector – PR & Marketing Manager

GOUDSMIT MAGNETICS GROUP

THE NETHERLANDS

TEL.: +31-(0)40 2213283

Info@goudsmit-magnetics.nl